Hollow Block in Bangladesh: Everything You Need to Know

A good shelter is one of the basic requirements of humankind. We have tried to take shelter under rigid structures for centuries for safety. With the advancement of technology and our economic situations, we have invented and adopted newer and safer ways to live. We can safely protect ourselves from environmental extremities. We can reside safely inside our houses from extreme heat to dangerously low temperatures. This is possible due to better design of our houses and better quality of building materials. We have modified the structural formation of our shelter to address the growing demands and amenities which an optimum shelter design must possess.

Modern building construction has come a long way. Currently, red bricks and concrete blocks are mainly being used worldwide. However, concrete blocks offer a lot of advantages over traditional red bricks. Concrete blocks help achieve cheaper and faster construction than other available methods. Concrete blocks come in mainly two variations.

- Solid Concrete Blocks

- Hollow concrete blocks

Both blocks are necessary for construction. The need for safe and structurally stable materials, keeping in view the economy of the whole project, paved the way for the usage of hollow concrete blocks. Moreover, hollow concrete blocks come in different sub-categories, and they are instrumental in several construction projects.

Checklist

What are Hollow concrete blocks?

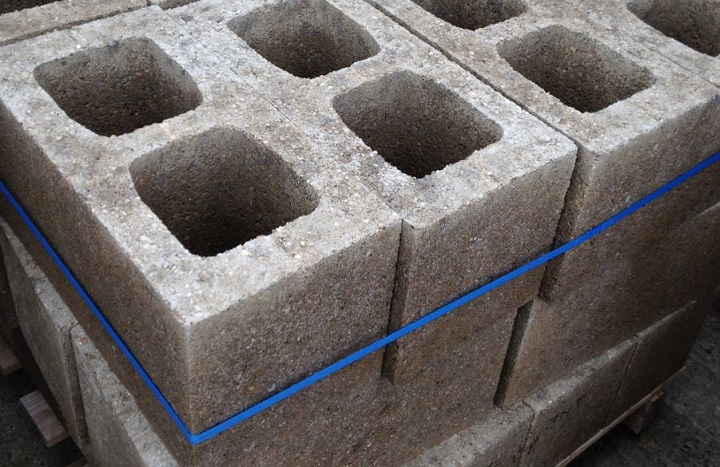

Hollow concrete blocks are mainly used as building materials in construction and are commonly used in compound walls. Hollow concrete blocks have gained high popularity due to their lower cost. Due to cavities, hollow concrete blocks are lightweight, making them easier to transport and use. Using hollow concrete blocks reduces the usage of cement in masonry works, which brings down the overall cost of construction by a lot.

Harmon S Palmer designed the first hollow concrete block in 1890. After a decade, he patented the design. Many companies started to manufacture hollow concrete blocks realizing their potential in the construction industry. The early blocks were cast by hand, and an estimated ten blocks were produced each hour.

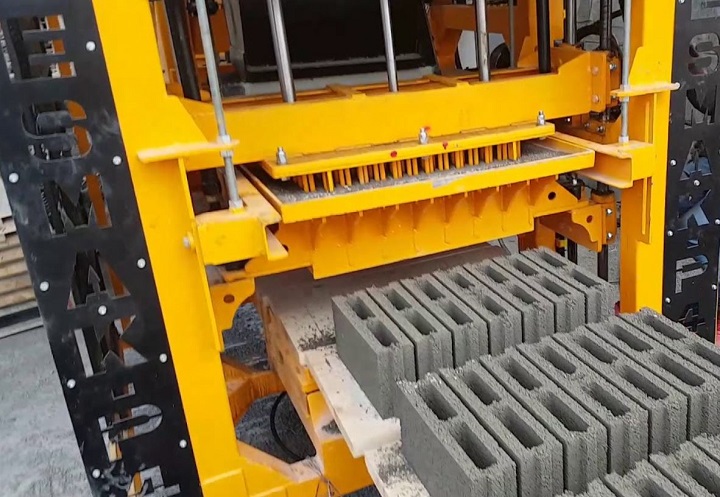

Currently, hollow concrete blocks are manufactured by highly automated machines where 2000 blocks can be produced each hour. Concrete blocks are used in almost all types of building construction globally. Bangladesh government’s recent commitment from 2019 to reduce climate and environmental hazards has paved the way toward the usability of hollow concrete blocks, replacing the local red clay bricks.

How are Hollow concrete blocks Made?

Hollow concrete blocks are made using Portland cement, water, sand, and gravel. The mixture is transferred to the Pan Mixer and the Horizontal Mixer. After completing the blending procedure, the required amount of water is added to the mix depending on climate conditions. The mixture is transferred to interlocking concrete block molds in the molding process, which have several mold liners in the outer mold box. Each mold shape is different depending on the design of the hollow concrete block. When the molds are filled with concrete, they undergo compaction by supplementing air or hydraulic pressure cylinders. In the curing process, the pallets are transferred to curing racks. The curing kiln gets very high in temperature that hardens the blocks. The last stage is cubing, where the kiln is rolled out and pallets are removed. After this stage, the cubes are carried outside in storage.

The whole manufacturing process is carefully monitored by using various sensors. The ratio of raw materials is measured electronically, the trapped moisture content in the sand and gravel are measured with ultrasonic sensors, and additives are calculated automatically by measuring other contents via different kinds of sensors. A good quality control environment is mandatory for maintaining high-grade concrete blocks.

Different Types of Hollow concrete blocks

Hollow concrete blocks are available in different shapes. These shapes give them different properties and usability. Hollow concrete blocks generally come in three grades.

- Grade A with a minimum density of 1500 KG/M^3

- Grade B with a density less than 1500 KG/M^3

- Grade C with a density greater than 1000 KG/M^3

Higher density hollow concrete blocks like grade A and grade B can be used in load-bearing walls, whereas grade C is only suitable for non-load-bearing walls.

Source: GharPedia

Hollow blocks come in 100mm x 200mm x 400mm, 150mm x 200mm x 400mm, and 200mm x 200mm x 400mm sizes. These blocks are generally gray but can also be manufactured in different colors. Here is a list of different types of hollow concrete blocks:

Concrete Stretcher Blocks

Concrete stretcher Blocks are most common in construction works. These blocks are used to join the corners of masonry units. These blocks have two holes or cavities and are placed with their length parallel to the face of the wall.

Lintel Blocks

Lintel blocks are also known as channeled blocks or beam blocks. These are “U” shaped concrete masonry units. They contain deep grooves along the length of the block. After appropriately placing the blocks, the grooves are filled with concrete and reinforcement. Lintel hollow concrete blocks are very useful on the top of doors and windows, transferring the load coming from the top.

Partition Concrete Block

These blocks are used in constructing partition walls. The hollow parts of the blocks are usually divided into two or three components. The partition block’s height is larger than its breadth.

Concrete Pillar Block

These blocks are considered double corner blocks as both of their corners are plain. They are used when two ends of the intersection are visible. According to its name, these blocks are very useful in pillars or piers.

Concrete Corner Block

As the name suggests, these blocks are used at the corners of the masonry units, at the end of the window, or door openings. These blocks are placed together with stretcher blocks. The plane end of the block is placed facing outside, and the other face is locked with the stretcher block.

Jamb Concrete Block

These are special kinds of blocks only used in places where an elaborated window opening is in the wall. These blocks are also connected to stretcher blocks. These blocks can provide space for casing members of windows.

Bullnose Concrete Block

These blocks are similar to corner blocks. The only difference is that bullnose blocks’ edges are rounded off.

Frogged Block

These blocks have frogs on their top, along with a header and stretcher. If placed on top, this space can be filled with mortar and can develop a strong bond with other blocks.

Column Block

These blocks are square with a cavity in the middle. These blocks are stacked on top of each other to create columns by putting reinforcement inside.

Advantages of Using Hollow Concrete Blocks

Hollow blocks show various advantages over other construction materials. These advantages have pushed its popularity globally in almost all construction works.

Design Flexibility

Hollow concrete blocks offer excellent design flexibility as they can be custom-made according to your demands. These blocks show remarkable flexibility in design and shape, along with incredible strength. The superior strength of hollow concrete blocks allows you to build practically anything you can imagine, from a single floor to multi-storied buildings, along with various accents like a pillar, arches, and more. Hollow concrete blocks can enhance yards as they are easy to work with and build retaining walls.

People do not have durability on their list while choosing a building material, and they want something that stands out and offers more design flexibility. Hollow concrete blocks offer precisely these features. These blocks can be adorned with different decorative materials.

Durability

A building made of hollow concrete blocks will require little to no maintenance after a very long time. It will almost last forever. Concrete blocks are one of the most robust building block materials known to us. Building with concrete blocks will make sure your building remains rigid and robust without facing any degradation or corrosion over time. Structures made of concrete blocks can withstand natural calamities like strong winds and even earthquakes. Hence, concrete blocks offer superior durability compared to other available building materials.

Energy Efficiency

Buildings that use hollow concrete blocks will be more energy-efficient than the same building made of traditional red bricks. This feature is very useful in hot countries like Bangladesh, where temperatures can soar up to 40 degrees outside. Hollow concrete blocks keep interiors cooler for longer by trapping the cool air inside. Hence, residents can save a lot of money on air conditioning by living inside hollow concrete blockhouses. This is also true in the winter season as these blocks can trap the warm air inside when the outside temperature drops.

Protection Against Extremities

A building consisting of hollow concrete blocks is highly resistant to extreme weather conditions. Therefore, hurricanes, tornadoes, floods, and storms will have little to no impact on a building built with hollow concrete blocks. In case of extreme flooding, interiors might get damaged, but the main structure of the building will remain intact.

Hollow concrete blocks can sustain under very high temperatures without cracking or severe damage. So, residents can safely live inside hollow concrete block homes as they will not sustain any significant damage during scorching weather conditions. It sustains after being exposed to fires.

Due to the lightweight factors, hollow concrete blocks are very useful in construction buildings in earthquake-prone regions. Bangladesh falls in a high-risk earthquake zone as it resides over a major fault line. Experts suggest that Dhaka might suffer the worst fate due to poor construction practices. So, it is high time Bangladesh adopted safer construction practices by implementing hollow concrete blocks.

Another benefit is hollow concrete blocks provide excellent sound insulation. So, residents can live peacefully in busy urban areas without worrying much about sound pollution.

Quicker Completion of Construction

Hollow concrete blocks are taller than other available building materials. So, using these blocks, construction can be completed much faster. Furthermore, it requires less mortar to join the blocks due to their design. It requires little or no plastering that speeds up the construction process. Moreover, hollow concrete blocks offer high dimensional accuracy and a consistent finish. So, hollow concrete blocks become ideal choices for load-bearing and partition walls.

Environmentally Friendly

Hollow concrete blocks are environmentally friendly. The manufacturing of traditional red bricks releases harmful fumes and chemicals into the air. Furthermore, it requires topsoil excavation, which negatively impacts the soil quality near farmlands. On the other hand, hollow concrete blocks are machine-made. Each block is almost identical to another, and it creates significantly less impact on the environment. Many countries have endorsed using hollow concrete blocks instead of traditional red bricks. So, hollow concrete blocks will help build a green city for the future generation.

Some Disadvantages of Hollow concrete blocks

Even though hollow concrete blocks come with many advantages, some factors fall behind.

Bleak Appearance

Some people consider the raw look of hollow blocks unsightly and utilitarian. However, some advanced technology allows it to be decorated with various render products.

Water Absorption

Hollow concrete blocks absorb water. Some retaining walls in contact with the earth will be wet most of the time. If the temperature goes below 0 degrees, the water starts to freeze. If this process repeats itself enough, cracks can appear in hollow concrete blocks. However, it is improbable this crack will spread throughout the wall.

Summary

Hollow concrete blocks are a relatively new phenomenon in construction in Bangladesh. Still, given the superior quality and advantages, it is expected to gradually take over the market, according to Prothom Alo. The Bangladesh construction industry is developing rapidly; to match with it, there is no alternative to hollow concrete blocks despite some disadvantages it might have.

Mir Concrete block started its journey with concrete blocks in 2004. They manufacture high-standard hollow concrete blocks, paving blocks, paving/parking tiles, etc. The company aims to aid Bangladesh in its journey to rapid urbanization in correspondence with modern and international standards.

Frequently Asked Questions (FAQs)

How heavy are hollow concrete blocks?

Ans: Hollow concrete blocks are generally around 16 KG.

Can I purchase hollow concrete blocks in Bangladesh?

Ans: There are many suppliers of hollow concrete blocks in Bangladesh, including Mir Concrete Block.

Are hollow concrete blocks better than traditional red bricks?

Ans: Considering all the factors, hollow concrete blocks provide more versatility to customers than traditional red bricks.

Are hollow concrete blocks strong?

Ans: Hollow concrete blocks are lightweight, durable, and very strong.

Are hollow concrete blocks good for homes?

Ans: They are good for homes due to their superior insulation properties.