The Ultimate Guide to Buying Concrete Blocks in Bangladesh

The use of concrete blocks has substantially increased in the last decade in Bangladesh. There are many advantages of using concrete blocks over traditional masonry units like red bricks. So, property owners are opting for the more modern and eco-friendlier alternative. The government of Bangladesh plans to reduce the use of red bricks to zero by 2025, according to The Business Standard. However, a lack of popularity in Bangladesh and people not knowing how to buy concrete blocks have impeded reaching the target. Property owners who plan to build their homes from scratch should know some essential information on the different purposes of concrete blocks. Different parts of a building are composed of different concrete blocks that are only suitable for those scenarios. Knowing the usability beforehand can help you to make a proper purchasing decision. This article aims to be your guide to buying concrete blocks in Bangladesh.

Checklist

Different Types of Concrete Blocks for Your Construction Requirements

Concrete blocks are the most common building material in the west. Almost all modern structures require concrete blocks to derive structural strength and other qualities. High-rise buildings require extensive load-bearing capabilities to sustain extremities. Concrete blocks have become an ideal choice in such cases.

The housing market in Bangladesh is booming. Many real estate developer companies are working day and night to build high-rise structures for housing. Dhaka is shifting its trend from building traditional six-storied buildings to twenty-storied or more. Traditional red bricks reduce the pace of construction work and are not suitable for high-rise buildings. So, the trend of using concrete blocks is rising in Bangladesh.

To purchase concrete blocks, you need to have a practical sense of the characteristics, performance benefits, and latest design guidance for concrete blocks in construction. Each type of block will offer its benefits if used appropriately. There are many different types of concrete blocks in the market. The following section will discuss what kind of concrete blocks you should purchase.

Aggregate Blocks

These blocks are available in a wide range of densities and compressive strengths. Different densities of aggregate concrete blocks are grouped into ultra-lightweight, lightweight, and dense categories. All concrete blocks are made from cement and add on different elements to alter the properties. Ultra-lightweight and lightweight blocks contain granulated or foamed blast-furnace slag, expanded clay, pumice, shale, and fly ash collected from various coal-based power stations. As the density increases, the load-bearing capacity or the strength of the block also increases. The first two blocks are used in internal and external walls and applications that do not require special load-bearing capacities. Lightweight blocks can provide lower levels of thermal conductivity due to the increased percentage of air. So, these blocks can offer better thermal insulation compared to denser blocks. Aggregate blocks typically weigh in the range of 8.5 – 20 KG and widths of 100mm. On the other hand, denser aggregate concrete blocks offer higher compressive strength, better acoustic performance, greater thermal mass, and low air permeability.

Source: Mir Concrete Block | Concrete Block in Bangladesh

Aircrete Blocks

Aircrete blocks offer the lightest option in the concrete blocks category. These blocks are made from cement, lime, sand, fly ash, and water. Aluminum powder is later added, which reacts with the lime to form tiny bubbles, causing the mixture to expand into a cake-like figure. After the mixture is partially set, they are cut into concrete block pieces. The concrete is then cured by steam to achieve its desired strength. The blocks’ lightweight nature allows them to perform well in heat insulation by reducing heat loss through external walls and junctions. These blocks are used in places like aggregate blocks. However, its lightweight nature does not make it a good option in places where high compressive strength is required. The general standard is 9N/mm2 or less for Aircrete blocks. These blocks are easy to work with and handle on construction sites.

The lightweight nature of Aircrete blocks makes it possible to manufacture large-format blocks, which can maintain a high margin of dimensional accuracy. This property can enable thin mortar joints, around 2 – 3mm, using a special kind of adhesive. Such adhesives can start setting in under half an hour and reach full strength in only 2 – 3 hours. Conventional mortar applications require a minimum of 24 hours before an additional load can be applied. These features allow an excellent pace in construction works, enabling large projects to be completed within a constrained time frame. The thermal characteristics of large-format blocks are the same as for standard Aircrete blocks. However, thinner mortar joints can cause a reduction in thermal bridging compared to conventional mortar joints.

Foundation Blocks

Foundation blocks are specially designed concrete blocks that are used below ground levels and provide a speedy and well-situated means to construct a base for supporting cavity and solid walls, beams, and block floors. As concrete blocks are precast block elements, the foundation work can be completed within a short time if they are used. Foundations blocks are manufactured both in Aircrete and Aggregate block types so that they are resistant to moisture, freeze/thaw, and sulfate attacks. If Aircrete types are used, compressive strength gets limited in the range of 3.6 – 7.3N/mm2. Lower-storied buildings can opt for these blocks.

On the other hand, high strength like 10.4 N/mm2 can also be achieved but only through aggregate blocks. Foundation walls are manufactured in various sizes that can span cavity walls that differ in widths. Some foundation blocks can be used above ground for solid wall construction.

Concrete Coursing Blocks

It is a particular type of block used for infilling small areas in walls to maintain a consistent level while laying blocks. These blocks are typically reduced in height, around 65mm. These come in very handy when doors or windows are placed in a wall. So, using coursing blocks, lintels above windows and doors can be leveled according to the rest of the wall’s height. Coursing blocks are suitable for almost all types of construction works, above or below damp-proof level, helping maintain a consistent height, and reducing the need for cutting blocks on site. For adjustment purposes, large concrete blocks are usually cut into required lengths, which can increase the cost as concrete cutting machines are required and introduce wastage of some blocks. So, concrete coursing blocks can help in such situations. These blocks are produced in Aircrete and Aggregate formats. Proper block types should be carefully picked to match the wall’s general build properties.

Hollow Blocks (Aggregate Type)

Hollow aggregate blocks contain cavities or holes inside them, passing from top to bottom. These blocks come in a variety of sizes and strengths. Hollow blocks usually carry 30 – 40% of the weight of a similar-sized solid concrete block. These blocks are widely used in the construction industry for general purpose works. It is easy to work with, making it a popular option for commercial works. One of the significant benefits of using hollow blocks is their incredible strength when reinforced with concrete fillings or steel rebar. These blocks can be used above and below damp-proof concrete levels.

Source: Mir Concrete Block | Concrete Block in Bangladesh

Cellular Blocks (Aggregate Type)

These blocks have cavities like hollow blocks. However, the cavities are blind, so they do not pass entirely through the blocks. It allows a full mortar bed on one face, beneficial for construction works. Cellular blocks can be used in one or both leaves of cavity walls. It can serve the purpose of a lower-weight alternative to solid aggregate blocks.

Furthermore, the reduced weight in cellular blocks does not take away its strength. It can perform similarly solid aggregate blocks. Other applications of cellular blocks include internal partitions and infill walling for framed structures. These blocks can achieve strengths from 2.9 – 10.4N/mm2.

Facing Blocks

These blocks are also known as decorative blocks. These are available in various colors and textures for both internal and external usage. The specialty of these blocks is their decorative properties without compromising in strength. These blocks have become quite popular in decorating modern living spaces. Commercial places or office places use these blocks to appeal to customers. They are incredibly well-suited for projects that require color consistency and textures.

Important Concrete Block Properties You Should be Aware of

Concrete blocks are available in different composite materials. The composition and manufacturing process determine the compressive strength of concrete blocks. They are also available in different sizes. Before purchasing concrete blocks, you must make sure what kind of blocks you require for your project. These properties of concrete blocks can determine the quality of your living standard inside the space.

Block Strength

Concrete block strength is an essential factor to decide before beginning project work. If you plan to build one or two-story buildings, concrete blocks with a compressive strength of around 3 N/mm2 are enough for cavity walls’ inner leaf. If a three-story building with a story height of more than 2.7m is considered, blocks with compressive strength of 7.3 N/mm2 or more are required for specific parts of the structure. However, depending on your project’s structural design and purpose, compressive strength requirements can change significantly. Sometimes different qualities of concrete blocks are required more than strength, such as resistance to chemical attacks. Building projects near the seashore can bring a whole new set of challenges to the table. So, it would help to determine what kind of block strength is suitable for your project.

Block Sizes

Concrete blocks are now available in the market in a variety of sizes. But you can purchase standard-size concrete blocks suitable for general purpose construction work that measures 440mm x 100mm x 215mm. For better understanding, you can compare this height with three red bricks and length as two red bricks with 10mm thickness of mortar joints. Furthermore, you can purchase alternative sizes according to your requirements. There are some alternatives readily available in the market that can improve the productivity of construction sites. There are Aircrete blocks with larger face sizes light enough to be handled manually, improving the pace and quality of construction work. Smaller-sized dense blocks can be used where manual handling is the only option.

Insulation

The insulation property of concrete blocks will heavily influence how you live inside your home. Insulation properties depend on the density and brand of your concrete block. By reducing the density in concrete blocks, manufacturers can drastically reduce the thermal conductivity. Thus, increasing the heat-insulation properties of the concrete blocks. It is an essential factor in places where it gets scorching during the summer, like in Bangladesh. Air conditioners can increase electricity bills during the summer seasons if your home is not protected against the heat. Furthermore, good insulation properties keep your home warm and comfortable during the winter season.

Acoustic Performance

The acoustic performance or outside noise can enter your living space depending on the concrete block structure, manufacturing method, block composition, the junction between different blocks, and the density of concrete blocks. If your property is near a busy street where you plan to build your home, keeping the acoustic performance of concrete blocks in mind can immensely impact how you live in your home. Noise pollution is one of the significant concerns in Bangladesh that is responsible for degrading the quality of life for many residents near streets, mainly in Dhaka. The unregulated honking of horns adds to an unbearable amount of cacophony in the city. Building homes with concrete blocks can somewhat mitigate these alarming issues.

All solid materials have a natural frequency of vibration. If a sound strikes the wall with the same frequency, the wall starts to vibrate in sympathy with the sound, translated on the opposite side. Light or thin partition walls suffer from noise pollution more. If the wall is made with denser material like concrete blocks, the natural frequency of that will be very low. So, only lower frequency sounds will transmit through the wall. As a result, concrete blocks play a significant role in reducing sound transmission.

Resistance to Fire

Fire-related incidents have tripled over the last 22 years in Bangladesh, according to Dhaka Tribune. So, making your home safe and resistant to fire is a crucial aspect of living in the city. You can check the quality of fire resistance before purchasing concrete blocks. Fire resistance properties vary significantly due to the choice of manufacturing material and density. You can check for additional information on the fire ratings of the concrete block that you wish to purchase.

Designs and Aesthetics

The design elements of your living space reflect your taste and personality. So, it is of paramount importance that you choose something that best suits your taste. With concrete blocks, you get a range of choices. If you are doubtful about which design element to go for, you can always consult with an architect who will walk you through the process of designing your dream home. Sometimes people relate concrete block homes to utilitarian aspects. However, there is a wide variety of colors and textures available in the concrete block market.

Sustainability

If you plan to build your home with sustainable materials, concrete blocks can offer the best option. Blocks contain a high level of recycled materials. Furthermore, they make less impact on the environment, unlike brick production, which can severely hamper the environment by releasing an extensive amount of CO2 and diminishing the topsoil, which is regarded as the life of agriculture. Using concrete blocks is a greener alternative in the construction workspace.

How to Buy Concrete Blocks in Bangladesh?

There are many concrete block manufacturers in Bangladesh. Concrete block prices vary depending on their types. You can purchase them directly from manufacturers or 3rd party suppliers. However, you should ensure you are purchasing authentic products by verifying them properly.

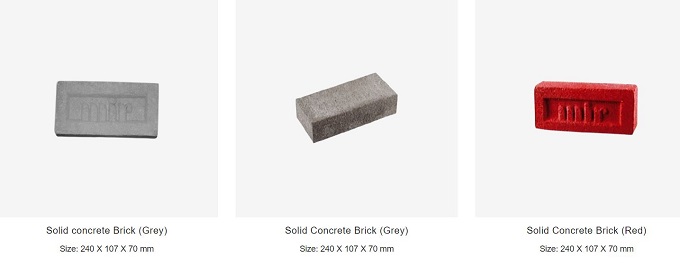

Mir Concrete Blocks offer one of the best quality concrete blocks in Bangladesh. The company’s solid blocks come in 240 x 107 x 70 mm sizes. The hollow blocks can be purchased in different thicknesses ranging from 390 x 190 x 90 mm to 390 x 190 x 240 mm. Furthermore, the company has a range of paver blocks suitable for your patios or driveways.

Summary

The Bangladesh government aims to popularize the usage of concrete blocks in upcoming years. All government projects should use 100% concrete blocks from the 2024 – 2025 fiscal year to curb brick kiln-related pollution. Concrete blocks are a sustainable building block material. Reducing our dependence on traditional red bricks will allow our environment to remain free from extreme pollutants. Furthermore, there are numerous benefits of using concrete blocks over other masonry units. However, you should make your purchase decision carefully to maximize the productivity and efficiency of your construction project.

Frequently Asked Questions (FAQs)

How can you know the quality of concrete blocks?

Ans: There are many tests to check the quality of concrete blocks. Drop test, corner test, chisel test, nail test, etc., methods can be applied to determine the quality of blocks.

How to know if a concrete block is hollow?

Ans: If you want to know this before purchasing, you can quickly identify hollow blocks through their cavities. If a wall is already built using blocks and you want to know whether it is hollow or solid, you can simply drill a part of the wall. If it provides a strong resistance all the way through, then it is solid, and if little resistance is shown, then the block is hollow.

What type of block should I purchase for my residential building?

Ans: You can choose hollow and solid concrete blocks depending on your requirements.

Are concrete blocks more expensive than red bricks?

Ans: No. You can complete your construction work at a cheaper rate with concrete blocks.

Is it an excellent choice to build my home with concrete blocks in Bangladesh?

Ans: Absolutely. Using concrete blocks is the most advantageous and eco-friendly option you can go with.